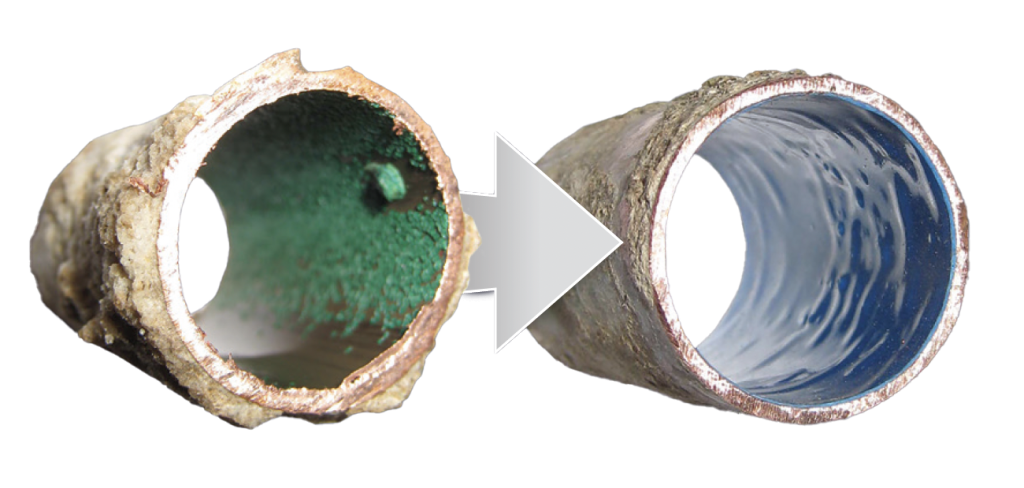

The AirKote® SLR process is utilized to install an internal NSF61 epoxy coating to leaking 1/2” through 1” copper and galvanized pipe sections up to 50’ in length. The epoxy coating is listed by ICC-ES file# PMG-1749

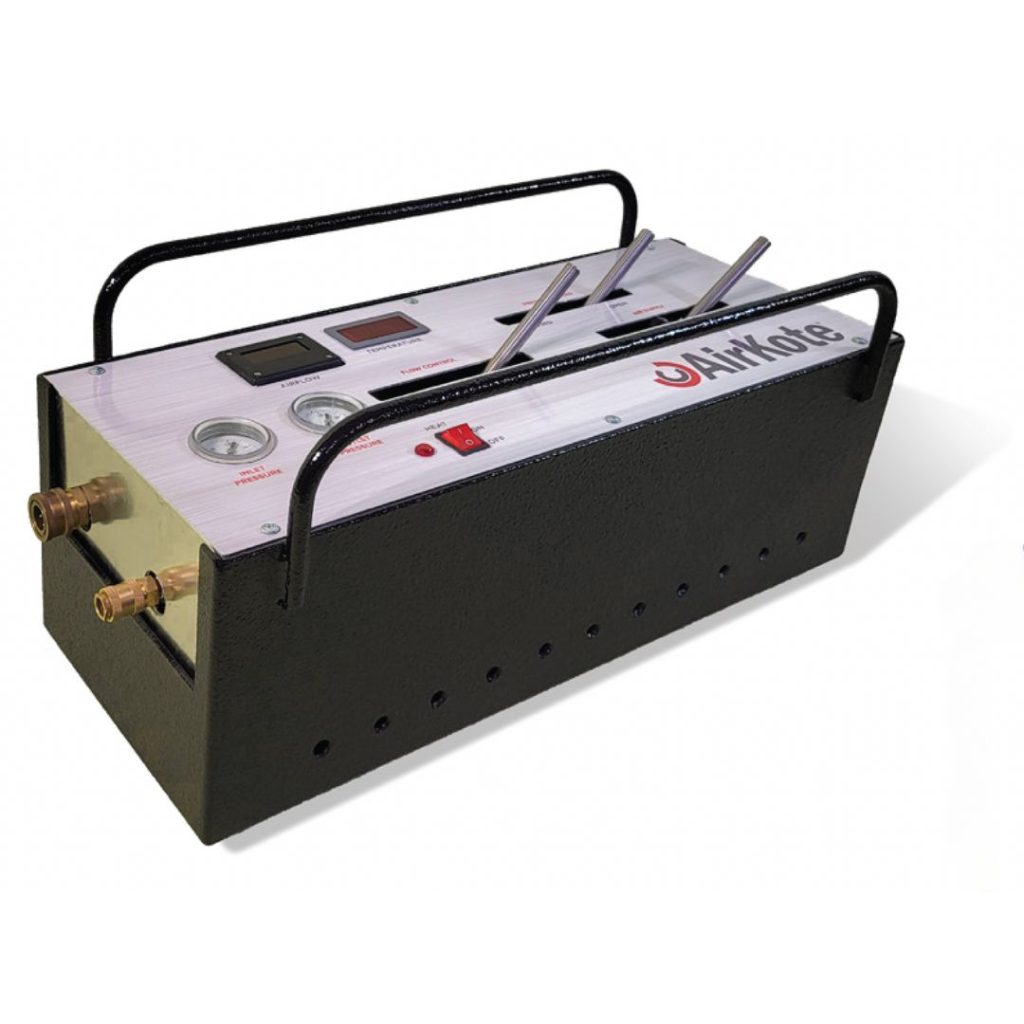

AirKote® SLR equipment has been designed to manage the application of the internal pipe coating while providing precise process control facilitating the sealing of pinhole leaks. To date the process has been applied to multiple thousands of leaking pipes in Orange County, CA with over a 98% success rate.

The AirKote® process and process control center are protected under US patents 8,486,314 and 9,027,507

The Process Control Box (US Patent 9,027,507) provides for the measurement and control of the airflow pressure, volume and temperature.

The AirKote process utilized a pneumatic dispensing system for the epoxy coating. The coating material is distributed in 450ML ratio pack cartridges and dispensed through a static mixing tip directly into the pipe system to be treated. This has the benefit of eliminating the field measuring and mixing of coatings.

Designed for 450ML plural component dispensing this pneumatic cartridge gun operates from compressed air provided by the Process Control Box.

The dust collector is utilized capture and collect the particles of dirt and abrasive media ejected during the pipe cleaning process.

AirKote® Epoxy is supplied pre-packaged in 450ML Ratio-Pack cartridges.

The muffler is utilized to catch the water forced out of the piping during the drying process and quiet the compressed air exiting the system.

This 2 ½ gallon pressure vessel is connected to the outbound shot tube during the coating step to receive any excess epoxy. The interior is lined with disposable filter material.

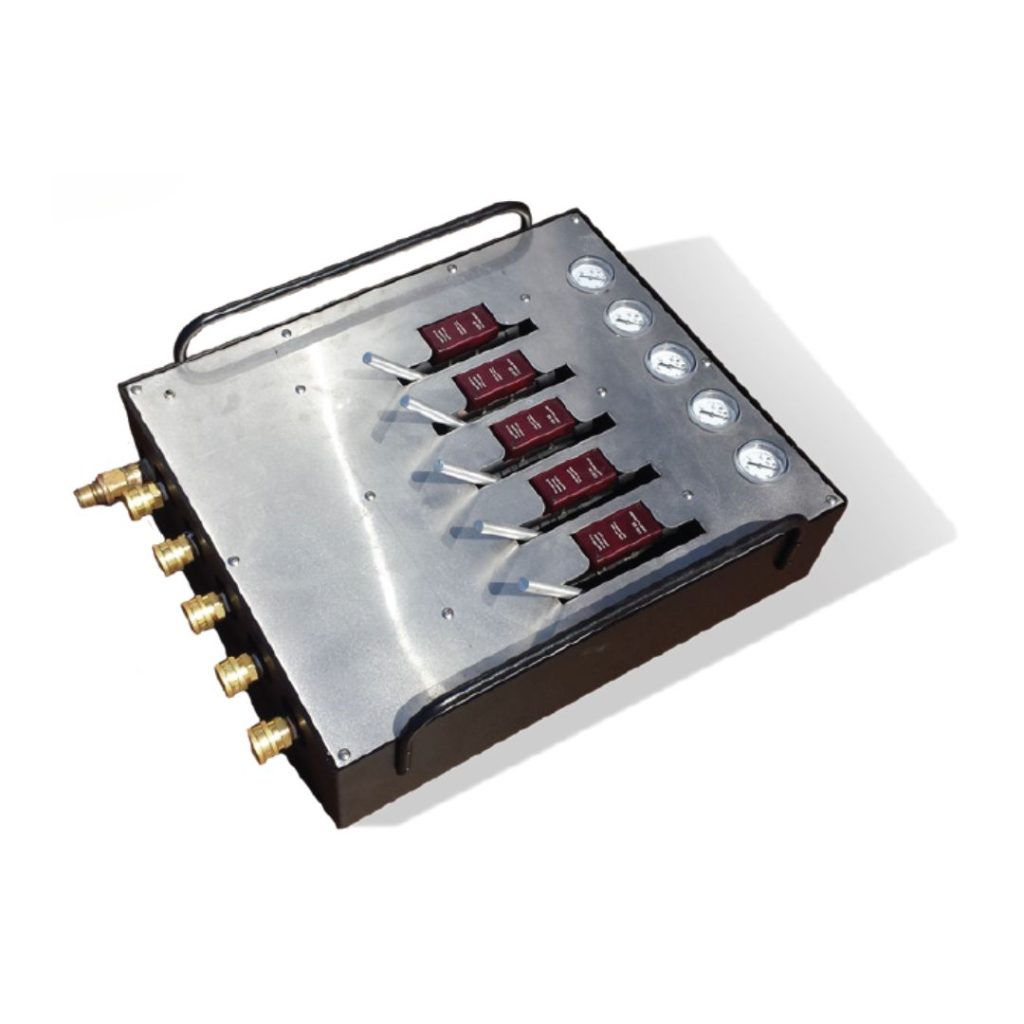

When used in conjunction with a Process Control Box systems of piping can be lined with up to five outlets.